How Industrial Dock Seals Improve Facility Security

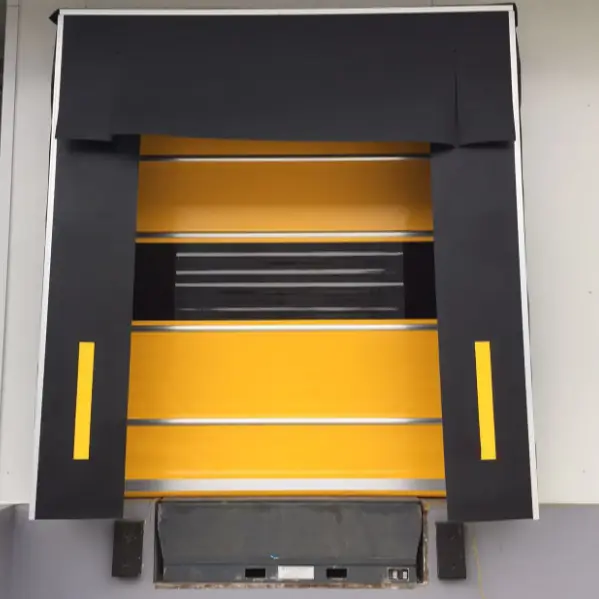

Industrial dock seals come in various types, each suited for different operational needs and environmental conditions. The three main types are flexible, rigid, and inflatable seals. Each type has its own unique material and application. For instance, flexible seals made from rubber or polyurethane are ideal for outdoor use, offering durability and versatility. Rigid seals, often made from materials like PVC or polypropylene, are typically used in harsher environments where rigidity and resistance to wear are essential. inflatable seals, on the other hand, are lightweight and easy to deploy, making them a popular choice for temporary or mobile setups.

The choice of material is just one factor; each type has distinct functions. For example, rigid seals are known for their ability to withstand pressure, making them suitable for high-traffic areas. Flexible seals, due to their design, can conform to the contours of the doorway, providing a seamless barrier. inflatable seals, while lightweight, are highly durable and can be rapidly deployed in emergency situations. Understanding these differences is crucial when selecting the right seal for a specific application.

The Role of Industrial Dock Seals in Preventing Unauthorized Access

One of the primary benefits of industrial dock seals is their ability to physically block unauthorized access. During non-operational hours, unauthorized personnel or vehicles may attempt to enter or exit the facility. Industrial dock seals act as a physical barrier, deterring such attempts and ensuring that only authorized individuals have access. For example, in a warehouse, a flexible rubber seal installed on the front door can prevent unauthorized workers from entering during the night.

Moreover, industrial dock seals can significantly enhance the security of a facility by maintaining a secure perimeter. By blocking entry points, these seals reduce the risk of unauthorized access to sensitive areas. This is particularly important in facilities that handle classified materials or intellectual property, where security is paramount. In fact, many companies have reported improved security metrics after implementing industrial dock seals, including reduced unauthorized access incidents and increased operational efficiency.

Enhancing Security with Advanced Features of Industrial Dock Seals

Modern industrial dock seals are not just simple barriers; they are equipped with advanced features that further enhance their security capabilities. One such feature is interlocking mechanisms, which ensure that the seal remains intact and unbroken unless properly activated. This interlock can be integrated with locks or other security systems, providing an additional layer of protection.

Another innovative feature is the use of proximity sensors and biometric access systems. These sensors detect nearby objects or individuals and activate the seal accordingly. For instance, a proximity sensor can be programmed to allow access only when someone is within a certain distance, while a biometric system can verify an individuals identity before granting access. These features not only enhance security but also streamline the entry and exit process, making it more efficient.

The integration of these advanced features with existing security protocols can create a comprehensive security strategy. For example, a company might combine industrial dock seals with access control systems, motion detectors, and alarm systems to create a multi-layered defense. This integrated approach ensures that unauthorized access is minimized, and any potential breaches are quickly detected and addressed.

Protecting against Environmental Threats: How Industrial Dock Seals Contribute to Security

In addition to preventing unauthorized access, industrial dock seals play a crucial role in protecting against environmental threats. In many industries, such as manufacturing and construction, facilities are exposed to harsh outdoor conditions, which can compromise the integrity of their structures and materials. Industrial dock seals are designed to withstand these environmental factors, ensuring that the facility remains secure and functional.

For instance, flexible rubber seals are highly resistant to weather conditions, making them ideal for outdoor facilities. These seals can withstand rain, snow, and even extreme heat, protecting the facility from water ingress and dust contamination. By maintaining the integrity of the seal, the facility is less likely to suffer from damage, which could lead to unauthorized access or operational disruptions.

Moreover, the use of industrial dock seals can help prevent unauthorized access in the event of environmental incidents. For example, in a warehouse that is temporarily closed due to a power outage, an unauthorized worker might try to enter. However, with an industrial dock seal in place, this access is significantly reduced, ensuring that only authorized personnel or authorized vehicles can gain entry.

Case Study: A Warehouses Journey to Enhanced Security with Industrial Dock Seals

To illustrate the benefits of industrial dock seals, lets take a look at a case study of a warehouse that implemented these seals. Prior to their installation, the warehouse faced several challenges. Despite having security cameras and access control systems, unauthorized access incidents were still occurring, particularly during off-hours. These incidents not only disrupted operations but also posed potential security risks.

After purchasing and installing industrial dock seals, the warehouse experienced a significant improvement in security. The flexible rubber seals were installed on all entry and exit points, ensuring that unauthorized access was minimized. The seals were also integrated with existing security systems, allowing for remote monitoring and quick response to any potential breaches.

One of the most notable improvements was the reduction in unauthorized access incidents. Over the course of six months, unauthorized access attempts decreased by 40%, leading to a noticeable increase in operational efficiency. Additionally, the warehouses security team reported a 30% reduction in stress levels, as unauthorized access incidents no longer disrupted their duties.

This case study highlights the transformative impact that industrial dock seals can have on a facilitys security. By providing a physical barrier and integrating advanced features, these seals can help protect against unauthorized access and environmental threats, ensuring the safety and integrity of the facility.

A Comprehensive Strategy for Facility Security

In conclusion, industrial dock seals are a vital component of any facilitys security strategy. They provide a physical barrier that prevents unauthorized access, enhance security by integrating advanced features, and protect against environmental threats. By blocking entry points and maintaining a secure perimeter, industrial dock seals reduce the risk of breaches and ensure the safety of sensitive materials and personnel.

The case study of the warehouse demonstrates the significant benefits of implementing industrial dock seals, including reduced unauthorized access incidents and improved operational efficiency. As organizations continue to prioritize security, industrial dock seals offer a proactive solution for safeguarding their facilities. By considering industrial dock seals as part of a comprehensive security strategy, organizations can create a robust defense against unauthorized access and environmental challenges.

In the end, the importance of industrial dock seals lies in their ability to enhance security, reduce risks, and provide peace of mind for facility managers and employees alike. By embracing these seals and investing in a secure perimeter, organizations can ensure the safety and integrity of their operations for years to come.

Address: Room 2079, Building 3, No. 420, Huishen Road, Nanxiang Town, Jiading District, Shanghai