How to Choose the Perfect Mechanical Dock Shelter for Your Business

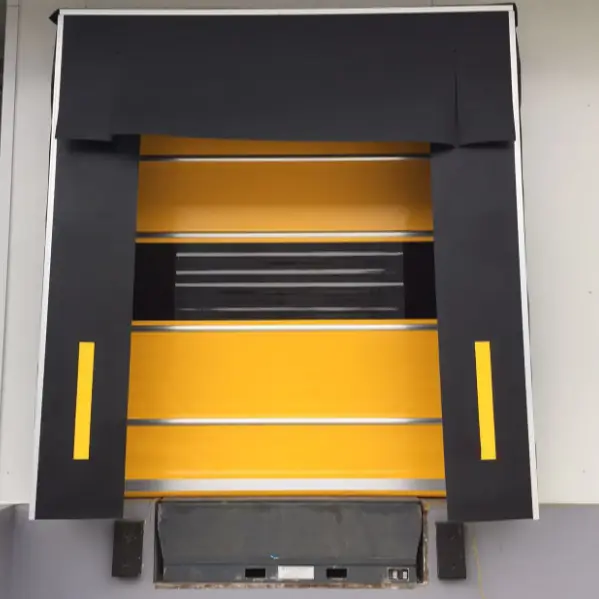

In today's fast-paced business environment, efficiency and reliability are paramount. Dock shelters serve as the backbone of logistics and supply chain operations, ensuring smooth entry and exit of vehicles and heavy equipment. A well-chosen mechanical dock shelter is more than just an accessory; it's a strategic investment in your business's success. Whether you're managing a small retail store or a large manufacturing facility, understanding the importance of dock shelters and how to choose the right one can make a significant difference in operational efficiency and cost savings.

A dock shelter is not a one-size-fits-all solution. The choice of a shelter depends on various factors, including the size and type of your loading dock, the nature of the products being handled, and the frequency of loading and unloading operations. Additionally, the type of business, such as outdoor retail or manufacturing, can dictate the specific needs. For example, a logistics company may require a high-capacity shelter with advanced security features, while a retail store might prioritize a weather-resistant and cost-effective solution.

Choosing the wrong dock shelter can lead to increased operational costs and potential damage, while the right one enhances productivity, reduces waste, and ensures employee safety. By taking the time to understand your specific needs and selecting the perfect shelter, you can streamline your operations and improve your business's overall efficiency.

Understanding Your Specific Needs

Each business has unique operational demands, and so do their dock shelter requirements. To select the perfect shelter, you must first assess your specific needs:

1. Loading Dock Size and Type: Consider whether your dock is for light goods, heavy equipment, or both. Heavy-duty docks may require more robust shelters to withstand the strain of machinery. For instance, a manufacturing facility handling large trucks and trailers will require a shelter that can accommodate the weight and size of these vehicles.

2. Product Nature: The type of goods you handlesuch as perishables, electronics, or heavy machinerydictates the shelter's requirements. For sensitive equipment, you might need a shelter with advanced thermal management systems to maintain optimal temperatures. In contrast, for perishables, a shelter with better weather protection and airtight seals might be necessary.

3. Frequency of Operations: The frequency of loading and unloading affects the shelter's durability and maintenance needs. Busy businesses require shelter that can withstand high traffic and frequent use, while low-traffic facilities might suffice with simpler designs. For example, a small retail shop with a low number of deliveries daily might not need as advanced or durable a shelter as a construction business with multiple heavy loads daily.

4. Seasonal Operations: If your business operates outdoors, weather conditions such as rain, snow, or extreme temperatures can significantly impact the shelter's performance. A shelter that provides excellent weather protection and insulation is crucial to maintain consistent operations throughout the year. For instance, a cold storage facility in a region with harsh winters may need a shelter that can keep cold air inside and warm air out, reducing energy costs and preserving goods.

5. Physical Space Constraints and Accessibility: The physical layout of your facility and the accessibility of the loading dock are critical considerations. The shelter must fit within the existing space, and the doors and entrance mechanisms should be accessible forklifts and other equipment. For example, a facility with narrow entryways might need a shelter that can fold or retract to allow easy access to the loading dock.

6. Compliance and Safety Standards: Ensure that the shelter meets all local safety and compliance standards. Features like emergency egress, ventilation systems, and robust construction materials are essential for compliance and safety. For instance, a shelter that complies with OSHA regulations can help prevent accidents and ensure a safe work environment.

Each of these factors plays a crucial role in determining the right shelter, ensuring it meets both practical and environmental needs.

Key Features to Consider

A mechanical dock shelter's value lies in its features. Here are the key attributes to prioritize:

1. Weather Protection: Essential for outdoor operations, these shelters protect goods and personnel from elements like rain, snow, or sun. Proper sealing and insulation are critical. For example, a shelter equipped with a rain shield and doors that seal tightly can provide excellent weather protection.

2. Durability and Longevity: High-quality materials ensure the shelter lasts longer, reducing the need for frequent replacements. Look for a balance between strength and cost-effectiveness. For instance, steel shelters provide robust durability but may be more expensive. In contrast, composite materials offer a cost-effective and durable alternative.

3. Ease of Maintenance: A well-maintained shelter saves time and money. Features like automatic doors or manual sliders can simplify upkeep, and regular inspection windows can aid in monitoring operations. For example, an easy-to-access door mechanism can make routine inspections and maintenance tasks less cumbersome.

4. Specialized Features: Depending on your needs, features like thermal management systems (to maintain temperature inside) or lighting (for visibility) can enhance functionality. For example, a shelter with a temperature control system can help preserve perishable goods and reduce energy costs.

5. Compatibility: Ensure the shelter integrates smoothly with your existing infrastructure, whether its an automated gate system or a manual workflow. For example, if your facility already has an automated gate system, a mechanical dock shelter that can work seamlessly with it is crucial.

6. Customization: Many shelters offer customization options, allowing you to tailor the shelter to fit your branding or specific operational requirements. For instance, adding a company logo to the shelter can enhance brand recognition.

Material Quality and Durability

The materials used in dock shelters directly impact their durability and long-term value. Common materials include:

- Steel: Highly durable and weather-resistant, steel shelters are cost-effective for heavy-duty use. For example, a steel shelter can withstand the weight and force of large trucks and trailers, making it ideal for manufacturing facilities.

- Vinyl: Lightweight and affordable, vinyl shelters are ideal for lighter applications but may lack in structural strength. For instance, a vinyl shelter might be appropriate for a retail store with low traffic but could be insufficient for a construction site.

- Composite Materials: Combining steel and vinyl, these shelters offer a balance of durability, strength, and cost-effectiveness. For example, a composite shelter can provide the robustness of steel with the added benefit of lower weights and easier installation.

High-quality materials not only enhance longevity but also contribute to noise reduction and efficient maintenance. Lower-quality options, while cheaper, may require more frequent repairs, increasing overall costs. For example, a shelter made with high-quality composite materials might have a longer lifespan and fewer maintenance issues compared to a cheaper, lower-quality option.

Real-World Success Stories

Real-life examples illustrate the benefits of investing in a good dock shelter:

1. Case Study 1: A retail business operating outdoors upgraded to a weather-protected shelter, reducing theft by 30% and improving customer satisfaction. For instance, a shelter with a robust security system and weather-resistant features can significantly reduce the risk of theft and vandalism.

2. Case Study 2: A logistics company faced challenges with damaged goods due to harsh weather. Installing a shelter with advanced thermal management reduced damage by 50% and prevented future issues. For example, a shelter equipped with thermal management systems can help maintain consistent temperatures, ensuring the quality of sensitive goods is not compromised.

These case studies highlight how tailored solutions can enhance productivity, safety, and cost efficiency.

Modern vs. Traditional Solutions

Mechanical dock shelters have evolved from traditional solutions, offering significant advantages:

1. Automation: Modern shelters often use motorized doors and sensors, reducing the need for a supervisor and improving efficiency. For example, an automated door system can be installed to open and close with the push of a button, making the process more efficient.

2. Environmental Efficiency: Many shelters incorporate energy-saving features, aligning with sustainability goals and reducing operational costs. For example, a shelter with integrated solar panels and energy-efficient lighting can help reduce your energy bill.

3. Environmental Compliance: Meeting environmental regulations is easier with advanced shelters, avoiding potential fines and ensuring compliance. For example, a shelter that complies with local air quality regulations can help prevent fines and ensure your business operates sustainably.

Traditional solutions, like manually operated gates, may be functional but are less efficient and require more supervision. Mechanical shelters offer a more reliable and scalable solution.

Professional Installation and Ongoing Support

The installation phase is crucial for a smooth operation. A professional service ensures the shelter is secure, well-maintained, and aligned with your business's needs. Regular maintenance by a reputable provider can prevent costly repairs and ensure the shelters longevity. For example, a company with a dedicated maintenance team can help schedule regular inspections and ensure the shelter remains in top condition.

Conclusion

Selecting a mechanical dock shelter is a multifaceted decision influenced by your business's unique operational requirements. By considering factors like material quality, durability, and specialized features, you can choose a shelter that enhances efficiency, safety, and cost-effectiveness.

This guide has provided a comprehensive overview of the key considerations. Remember, the right shelter is not just a necessity but an investment in your businesss success. Take the time to evaluate your needs thoroughly, consult with experts if necessary, and make an informed choice to optimize your dock operations.

By following this guide, you can ensure that your business selects the perfect mechanical dock shelter, leading to improved efficiency, reduced costs, and enhanced operational safety.

Address: Room 2079, Building 3, No. 420, Huishen Road, Nanxiang Town, Jiading District, Shanghai